Lots of printshops offer multiple printing options, such as digital printing and screen printing. At https://onlineprintedtees.com/,, we tell you what is best for you. There are advantages to each, depending on the type of design you are using, and the quantity that you want to make.

Here’s a quick rundown of when to use DTG printing on shirts vs. screen printing.

When to Use DTG printing on shirts

Direct-to-garment (DTG) printing on shirts offers extensive color options, and you can easily print detailed designs and photorealistic images.

1. Small quantity runs

Small runs and one-offs. Your DTG printer will love small runs. You can always advertise that your print shop provides low minimums, and full-color prints on light or dark apparels. Additionally, if a consumer asks for five to ten or twenty more shirts, you can have reorders fast and easy with just a little setup time.

2. Photo realistic quality on garment printing

It provides precise and “realistic” images. A DTG printer will give you images in high resolution with high-quality details. Plus, you will have many color options to choose from.

3. Fast printing method for t-shirt printing

It provides a quick turn time. Compared to other printing methods, you can offer a quicker turn time with DTG printing on shirts, since you don’t have to color-separate or vectorize the design. With DTG printing on shirts, you could prepare, print 10 shirts relatively fast; comparatively, screen printing a five-color job on 10 shirts could take up to hours, from separations then to the cleanup.

4. Compete others with these DTG garment printers

Custom is your new first name. With customization trends that continue to be at the top of mind at retail, you can fulfill highly customized orders with your DTG printer, and compete with online T-shirt companies.

5. Making sample pieces easy

With a DTG printer, you can print lots of sample T-shirts and give them out to customers so they can literally wear your design and experience its high-quality.

6. DTG printer Investment Affordable

Affordable investment costs. Depending on the type of DTG printer you have, your initial investment can go a long way. Obviously, as printers increase in price, they operate at higher speeds. Generally though, for your investment, you could see profit with the first 150 shirts you print. With https://merlinembroidery.net/, we will print shirts that will showcase the design you made.

7. What are the best quality t-shirts for DTG printing?

DTG printer can print custom designs on fabrics only. Generally, fabrics that are made of polycotton or 100% polyester are best to use with DTG printers. 100% cotton t-shirts may not be good for printing. Because they can shrink easily and it affects the print quality.

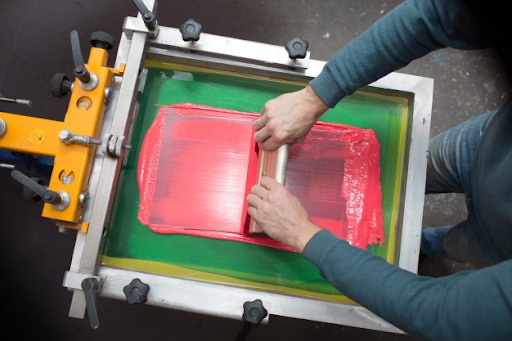

When to Use Screen Printing

Screen printing is cost-effective for larger runs of simpler designs with fewer colors. However, this method isn’t as budget-conscious for multiple-color designs, and you can only print one design run per set of screens you set up. The upfront investment is also greater than other imprinting methods – for a small print shop that invests in a new manual press, flash unit, small conveyor dryer, and a prep area, expect costs of $15,000 to $20,000.

1. Ideal for simple designs with one color

Kick it with one-color designs. Screen printing is an ideal choice for simple designs with one color – like logos, graphics, or text. Be aware that screen printing might not be the right fit for designs with a lot of colors or photographic accuracy. And while you can achieve fairly accurate and very vibrant spot colors, gradients or shades might be harder to achieve.

2. Best method for large quantity runs

High-volume runs. With each color you add, setup takes more time, because screen printing has more steps than other digital printing methods, like DTG. However, the more T-shirts you print, for example, the lower your time, labor, or other cost investments. Example: If you’re printing in bulk for a summer camp, sports team, or big event, screen printing would be a great decorating method.

3. Suitable for all types of materials

Works on lots of substrates. Screen printing allows you to print on almost any flat surface and material, including fabric, plastic, metal, and wood. This means that the design you create can go onto T-shirts, signs, business forms, and more.

4. Fast production

If you invest in an automatic screen-printing press, you can print a shirt and get it on a dryer belt every three to five seconds, if you’ve satisfied your pre-press requirements.

Today, it’s important for shops to diversify and offer multiple types of decorating options. We recommend that when you offer more than one type of printing, you’re very conversant in when to use each to benefit your customer – and your shop’s profitability.

Conclusion

Here at https://onlineprintedtees.com/ we provide you the best option for your design and artwork. We are experts and professionals who want the best for their customers. You can always count on us when it comes to screen printing and DTG printing. We provide high-quality work even with large quantities of shirts and apparel.